Ever saw a freshly smoothed-out gravel road? how it gets so tidy and even? That’s not magic, but the power of a grader.

If you’re working a construction site, fixing up farm roads, or prepping for a foundation pour. Graders are the precision tool you need to make the surface just right. Let’s understand its function, uses, common issues and maintenance needs to operate one like a pro.

Worldwide Construction Machinery (WCM) is the pit crew for farmers, tradies, and site managers chasing quality grader machines and other heavy-duty gear. We’re family-owned, straight-talking, and loaded with over 40 years of industry experience.

Let’s pour some of our knowledge to you.

What is a Grader?

A grader (also called a motor grader or road grader) is a piece of heavy machinery with a long, adjustable blade used for creating flat surfaces. It does not roar like a dozer or lift like a loader, but it’s just as critical. Especially when you need levelled ground before laying concrete, bitumen, or even turf.

Grader machines come in two main types:

- Motor grader: Self-propelled with engines, typically used in large-scale jobs.

- Grader for tractor: Attach to the back of a tractor, perfect for farms or smaller properties.

Graders are used in roadwork, sports field prep, site levelling, mining roads, and even landscaping. Any surface where you need precision and smoothness, needs a grader.

Where Did Graders Come From? A Bit of Grading History

Before engines and hydraulics ruled the scene, graders were pretty basic. Wooden blades were drawn by horses or humans. They were used to smooth out the soil in agricultural fields. As road building picked up in the 1900s, so did grader design.

By the 1920s, first self-propelled grader was manufactured by Russell Grader company. That consisted of grader blade attached with an engine.

Fast forward to today, and you’ve got computer-assisted controls, GPS levelling systems, climate-controlled cabins, different grader operator positions, and blades that slice through rock and clay like butter.

The journey from horse-drawn planks to ace grader shows just how far we’ve come, upgrading the essential machines with our growing needs.

Components of a Power Grader

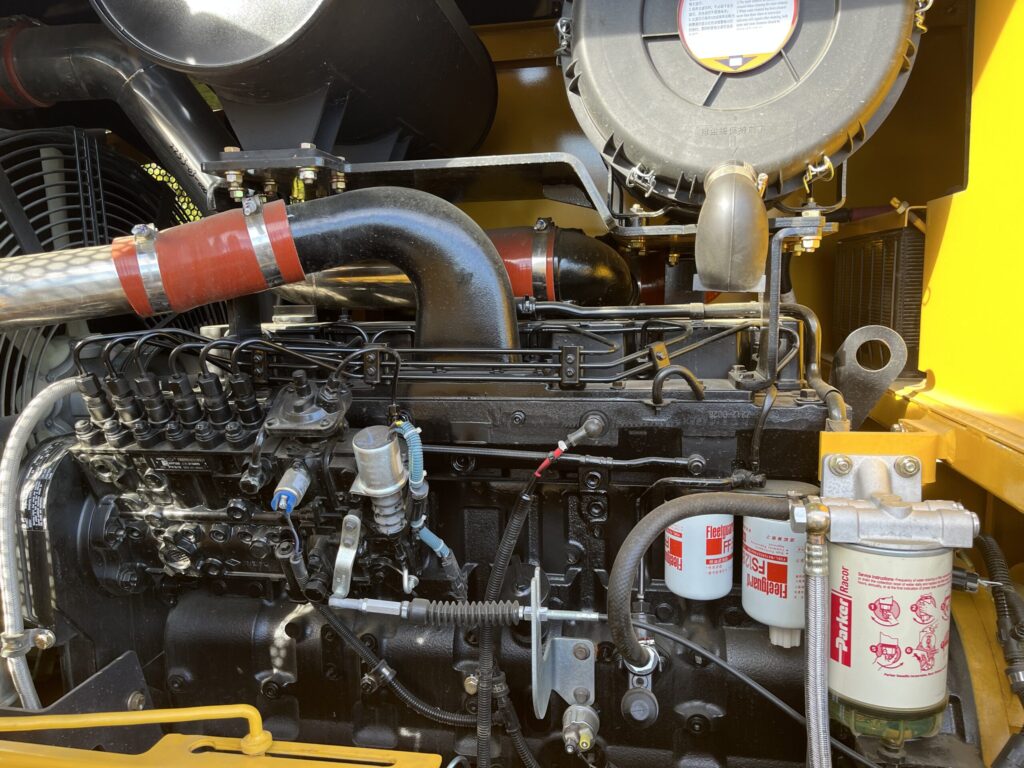

Following are important moveable components you’ll find under the hood of a modern grader machine.

1. Mouldboard (Main Blade)

This curved blade is the heart of the operation. It cuts, pushes, spreads, and levels materials like gravel, soil, or sand.

2. Circle Drive

It allows the blade to rotate for angled grading when building cambered roads or drainage slopes.

3. Rippers or Scarifiers

These teeth-like tools are mounted at the rear or front. They break up hard surfaces & make grading easier and more effective.

4. Articulation & Frame

The machine’s frame can bend in the middle, giving graders tighter turning ability. That’s a must-have for narrow workspaces.

5. Hydraulics System

It controls all blade movement, raise, tilt, angle, slide. Modern systems are intuitive, helping the grader operator work with pinpoint accuracy.

6. Cab & Controls

E.g. ergonomic seats, joysticks, and dash panels. It’s like sitting in a cockpit built for levelling land.

Where the Graders Can be Used?

These machines come with a huge versatility, from city roads to village fields. Some sites where you’ll see a grader for sale in action are:

Construction & Road Work

- Cutting subgrade layers for roads.

- Maintaining gravel or dirt roads.

- Creating drainage ditches or cambered edges.

Agriculture & Farms

- Level off planting fields.

- Smooth out tractor tracks or livestock paths.

- Maintain access roads or farmyards.

Mining & Industrial Sites

- Level off haul roads for trucks.

- Prep and maintain open-pit paths.

- Keep operations smooth and dust under control.

Landscaping & Site Prep

- Prepping large-scale housing estates.

- Contouring land before turfing or paving.

- Laying foundations with millimetre precision.

How to Operate a Grader?

Operating a grader takes practice and feel, much like towing a trailer or reversing a ute with a toolbox full of gear. You’ll begin with:

1. Pre-Start Checks

- Check fuel, hydraulic oil, engine coolant.

- Inspect tyres or tracks.

- Make sure the blade is clean and securely mounted.

2. Mounting and Start-Up

- Hop into the cab, adjust your seat and mirrors.

- Start the engine and run idle for a few minutes.

3. Blade Positioning

- Use hydraulics to raise, lower, tilt, or angle the mouldboard.

- Keep it flat for base grading; angle it for side pushing.

4. Grading Techniques

- Work in overlapping passes.

- Adjust the blade mid-pass to correct bumps.

- Keep speeds low and steady.

5. Finishing

- Use light blade pressure for the final pass.

- Compact if needed (some grader road builds require rolling).

Learning how to operate a grader is about rhythm, blade feel, and timing. It’s a skill, and once you’ve got it, it’s super satisfying.

Common Grader Problems You Can Face

Like any workhorse, graders also face problems with daily use. But don’t worry, you can wipe them off with simple hacks.

Issue | Cause | Fix |

Uneven grading or cutting | Blade angle too steep or not level | Adjust hydraulics, check tyre pressure |

Hydraulics lagging | Low fluid or dirty filter | Top up or flush system |

Sluggish articulation | Poor grease or damaged pins | Grease up or replace bushings |

Engine overheating | Dirty radiator or fan failure | Clean or replace components |

Electrical system failure | Blown fuses, loose connections, or faulty switches | Do troubleshooting & replace the damaged components |

Tyre damage | Wear & tear due to excessive use | Check tyre balancing & replace the tyres |

The problems will be minimum if you keep your machine in a good shape with routine maintenance.

Grader Maintenance Checklist

The scheduled maintenance we suggest for grader machines involves:

Daily:

- Check fluids.

- Inspect tyres or tracks.

- Clean the cab and check all controls.

Weekly:

- Grease articulation and blade pivot points.

- Inspect hydraulic lines for wear.

Monthly:

- Change filters.

- Test blade calibration and adjust articulation.

Pro Tip:

Train your grader operator to do visual inspections. A 10-minute check before starting can save you thousands in repairs later.

Looking for the Right Grader on Sale?

Explore Top Quality Graders with Worldwide Construction Machinery

At WCM, we’re your partners for every heavy machine job. With over 50 models ready to go and 40+ years of industry knowledge, we’ll help you find the right fit. If you’re after a compact grader for tractor, a powerful site-leveling power grader, or a reliable used option, we’ve got the stock and advice.

Plus, we offer full-service support and competitive pricing. Because we care more about your job site running right than pushing a sale.