Construction is no walk in the park. Every job, from building a driveway or digging up a mining site, needs the right machine. While the wrong gear can slow down your project, hit your wallet or even jeopardise safety on site.

So, how do you make the right choice?

Let us guide on function & applications of different types of construction equipment. So, you can pick the needed gear for every job in no time.

Worldwide Construction Machinery (WCM) been helping Aussies like you since 1982. From earthmoving machinery to roadwork rigs and everything in between. We serve up experience, trust, and top-shelf service with every deal.

Let’s explore the construction machinery Australia and how they get the job done.

Types of Construction Equipment

Knowledge about different types of construction vehicles isn’t just for site supervisors. Contractor, farmer, or land-owners all should know their gear. So, there can be better decisions, fewer breakdowns, and faster job completions. Because you can’t enter a race with the wrong tyres, same logic here.

Here are some leading players of the game.

A. Earth-Moving Construction Equipment

Earth moving machinery has been in scene since 1920, when the first bucket wheel excavator was used as a mining tool.

After that, there’s a constant rise in sales volume of construction equipment. Thanks to the infrastructure development in US & China, sales figure of earthmoving machinery reached to 41 billion US dollars in 2023. (Source).

1. Excavators

Excavators are versatile machines for digging trenches, lifting heavy materials, demolition, and forestry operations. They come in different sizes and configurations, including:

- Crawler Excavators: Equipped with tracks for stability, they are used in heavy-duty digging and lifting on uneven terrain.

- Wheeled Excavators: Featuring wheels instead of tracks, their mobility suits the projects that require frequent relocation.

- Mini Excavators: Compact and lightweight for smaller tasks and confined spaces, they offer more precision and flexibility.

Excavators are equipped with a boom, dipper (or stick), bucket, and cab on a rotating platform known as the “house.” The hydraulic system enables smooth operation of the arm and bucket, and allow for efficient excavation and material handling.

Read More: The Ultimate Excavators Buying Guide for Every Contractor

2. Wheel Loaders

Wheel loaders are built to scoop and move large volumes of material. They are heavy-duty vehicles with a front-mounted square wide bucket, used for:

- Loading materials into trucks

- Moving materials around the site

- Excavating

- Clearing debris

Wheel loaders come in various sizes, all speed and manoeuvrability. So, they can easily handle frequent material handling over short distances. The quick hitch feature adds variety of tools to move everything around, from gravel to sand.

Explore Our Variety of Loaders

3. Backhoe Loaders

Backhoe loaders combine the capabilities of a loader and an excavator into a single unit. They have a tractor-like chassis with a loader bucket on the front and a backhoe on the rear. Dual functionality enables them for:

- Excavating trenches

- Digging foundations

- Loading and carrying materials

- Backfilling

- Breaking asphalt

- Landscaping

- Utility work

Variations include center-mount backhoes with standard configuration. and side-shift backhoes for digging closer to walls or obstacles. They come in compact size, so, easily cover urban areas or limited spaces.

4. Motor Graders

Need to fine-tune your surface for paving? Graders are your go-to for levelling surfaces and maintaining dirt roads. Their applications range from:

- Road construction and maintenance

- Preparing base courses

- Spreading and levelling aggregate or soil

- Finishing subgrades before paving

- Levelling building foundation pads

- Creating drainage ditches

- Contouring landscapes

Their specialised long blades give a smooth finish to any surface. It is adjustable & allow for precise civil works and even snow clearing in frosty regions.

Shop from WCM Graders in Perth

5. Skid Steers

Tight job site? No problem. Skid-steer loaders are compact machines with remarkable agility and versatility. Key features include:

- Zero-Radius Turning: Differential steering allows the machine to turn within its own length.

- Versatility: Capable of digging, grading, lifting, and snow removal.

- Compact Size: Handle confined-space work and urban construction sites.

Their lift arms can attach to a wide variety of buckets for landscaping, site clean-up, and small-scale excavation.

6. Bulldozers

Do you know? Bulldozer is the key machine used in World War II. Ranked 4th after submarines, radars & planes by William F. Halsey. They are all about pushing the heavy materials, like hard ground, soil, sand, or rubble.

Their heavy-duty front blades are designed for:

- Land clearing

- Grading

- Road building

- Excavating shallow levels of surfaces

Bulldozers come in two main types:

- Track-Type Bulldozers: Durable enough to operate in rough terrain.

- Wheeled Bulldozers: For smoother surfaces and faster travel speeds.

They also have a ripper at the back for ripping hard materials or heavily compacted ground.

7. Scrapers

Scrappers are designed to dig into soil, collect it, and transport it to another area. These machines are useful for:

- Highway projects

- Large earthmoving jobs

- Reducing the need for multiple machines

They can efficiently load, transport, and discharge material. So, you won’t need multiple machines for large-scale construction projects.

Material Handling Construction Equipment

The history of human-built structures dates back millions of years. So does the need for material handling and machinery for construction.

Along the timeline, different types of construction vehicles have been used. From early wooden carts and sleds to modern machinery like cranes and conveyers. Let’s get to know them one by one.

1. Cranes

Cranes are machines used to lift heavy loads, materials, and goods. There are different variants of them, including:

- Tower Cranes: Used in the construction of high-rises and skyscrapers.

- Mobile Cranes: Can be moved to different locations on a construction site.

- Overhead Cranes: Lift heavy materials in industrial settings across a workspace.

Wherever height is involved, you can trust the cranes blindfolded.

2. Forklifts

Not all construction and equipment needs are outside. Forklifts shine in indoor setups and warehouses. Their long, extendable arm and a set of forks are used to:

- Lift and transport heavy loads

- Move materials from one area to another

- Stack materials

- Load or unload trucks

Forklifts are widely used for material handling in various industries.

Check Out Our Collection of Forklifts for Sale in WA

3. Telehandlers

Telehandlers, or telescopic handlers, combine the features of a forklift with a boom. Their reach goes to any heighted or hard-to-reach spot for:

- Placing loads

- Roofing

- Framing

- Stacking materials

Telehandlers come with different types of attachments enhancing their versatility on construction sites. Such as buckets, pallet forks, and lifting jibs.

Browse Our Range of Telehandlers

4. Conveyors

Need consistent flow of aggregates or bulk materials? Conveyor systems offer you automation and speed. Especially needed in mining and material processing industries.

The first conveyor belt was invented in 1892 by Thomas Robbins to transport coal and ore. It won the grand prize at the Paris Exposition World Fair in 1900. Since then, they reduced a significant labour need by transporting materials over long distances.

5. Dump Trucks

Whenever you need to transport large amounts of earth, gravel & demolition waste. Dump trucks are one of the important types of construction vehicles. They are built to carry and dump loads efficiently.

The biggest dump truck in the world can carry 496 tonnes of material. Sounds fascinating? You can imagine the range of their power with that.

6. Crushers

When demolition’s done, crushers turn rubble into reusable material. They breakdown rocks, stones, and concrete for:

- Recycling construction materials

- Reducing waste on-site

- Preparing materials for further processing

Crushers come in various types each suited for specific applications. E.g. jaw crushers, cone crushers, and impact crushers.

7. Concrete Mixers

Their function is quite obvious from their name. They offer on-the-spot mixing to save time and adds to the strength of structural builds.

Concrete mixers come in stationary & movable variants catering to different project needs. Their common configurations include drum mixers and truck-mounted mixers.

8. Rollers

Before the final layer goes down, road rollers compact the base. Whether it’s a vibratory roller or pneumatic one, they make your surface ready for the long haul.

Their functions include:

- Compacting soil, gravel, concrete, or asphalt

- Preparing surfaces for road construction

- Giving a smooth and even finish

You can use smooth wheel rollers for shallow layers. Or get sheep-foot rollers if you need deep compaction.

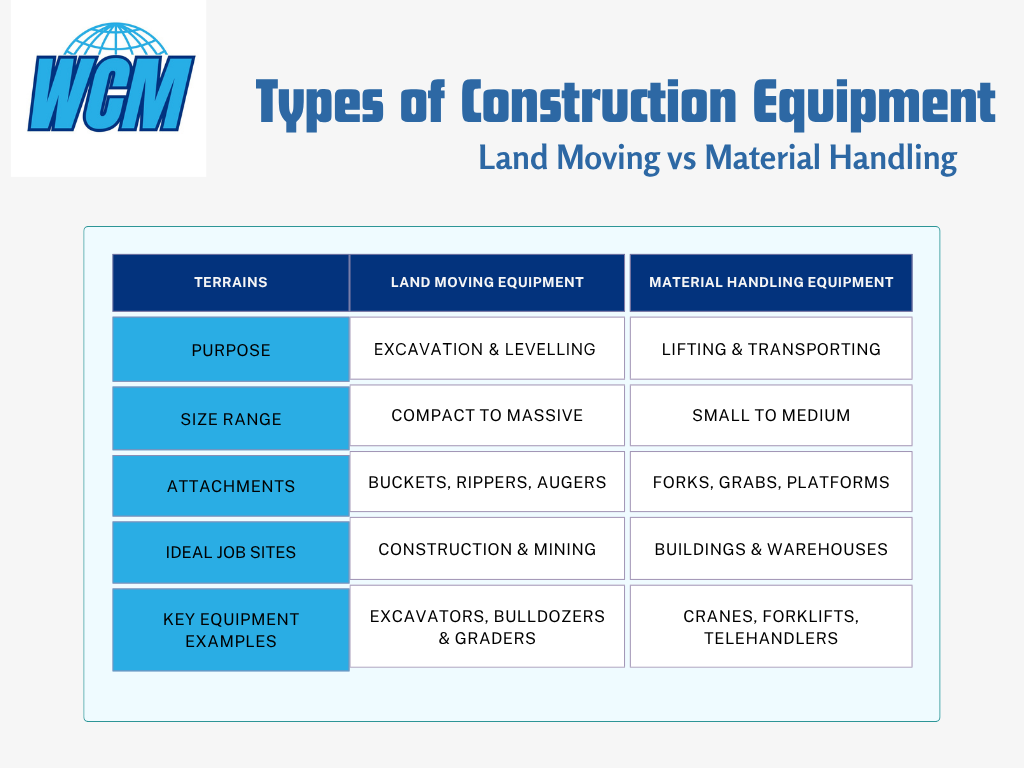

Comparing Earthmoving vs. Material Handling Construction Equipment

With the right knowledge, you can get the job done faster, safer, and smarter.

Construction Equipment in Perth: Local Needs, Global Quality

If you’re based in WA, you know our soil, climate, and site sizes are different. Construction in Australia means:

- Labour Exposure to extreme environments

- Strict regulations of NHVR for construction equipment

- Safety compliance with govt bodies like Safe Work Australia

That’s why our Construction Equipment in Perth is equipped with durable design & required accessories. So, it can handle local conditions & Aussie challenges easily.

If you’re working on road construction in Karratha or excavation projects in Albany. We equipment with suitable specs for that. From high horsepower vehicles to smaller & agile units. Every unit gives the optimal performance for your needs.

What to Consider Before Buying Construction Equipment

- Purpose of Use: Is it for a one-off job or regular work?

- Terrain Type: Some machines work better on rocky grounds, others on soft soil.

- New vs. Used: Do you prefer reasonable price or long-term warranties?

- Servicing & Support: Is your provider offering it?

- Attachments & Versatility: Look for models that support multiple attachments.

Searching for Quality Construction & Excavation Machinery for Sale?

Choose Confidence with Worldwide Construction Machinery

Since 1982, Worldwide Construction Machinery (WCM) has been Australia’s trusted pit crew for all things machinery.

We bring over four decades of industry experience to your site. With our construction machinery for sale, expert servicing, and a solid second-hand range to save your budget.

Browse Our Range of Construction Equipment and see what we’ve got revved up for your next project.